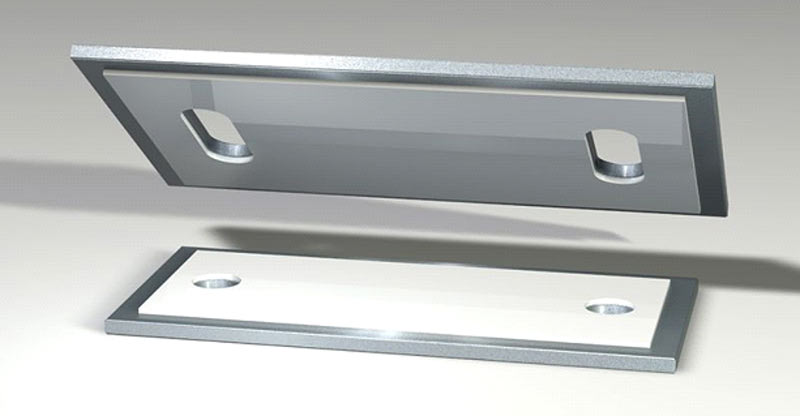

Sliding Bearing Pad

For application where horizontal displacement exceeds ±2 inches (50mm) sliding elastomeric bearing assemblies may provide an economical solution. The low friction sliding surfaces allows a standard laminated elastomeric bearing to accommodate unlimited horizontal displacement without increasing the height of the bearing assembly

MER developed simple and economical sliding bearing system consists of 100% virgin PTFE with MS plate backing plate system. These systems operate with the lowest coefficient of friction over a broad range of temperatures. And also we offer filled PTFE with low coefficient of friction and chemical inertness for higher loading areas.

This structural bearing surface is bonded to a back-up steel plate with a high temperature homogenous epoxy system that is cured under precise heat and pressure in hydraulic presses. All MER bearings are factory bonded using strictly controlled, semi-automated procedures, developed to eliminate poor quality field-made bonds. MER bearings can be obtained with elastomeric back-up which will enable the system to accept live-load rotations.

Features

- Low friction coefficient. The beam end can freely slide on the PTFE surface.

- Dimples on surface. With dimples on PTFE for contain lubricant to ease the sliding movements.

- Superior flexibility. Adapt to the rotation of the beam end.

- Large shear deformation. Can satisfy the horizontal displacement of the superstructure.

- Excellent isolation effect. Can reduce the impact force from the live load and earthquake.