Laminated Bearing Pad

Longer prestressed concrete box beam bridges require that the bearings accommodate higher loads and greater thermal expansions. In order to increase the longitudinal movement and rotational capacity of elastomeric bearings while increasing their compressive strength, thin steel laminate reinforcement is placed between the elastomeric pads. The greater height of total elastomer allows for more movement, while the steel load plates prevent excessive bulging of the elastomer.

In case the compression minimum load is under 30 kg/cm2, the bearing should be anchored to the structure to avoid its movement. This type is especially useful where traction and high horizontal forces are to be transmitted.

It can transmit small movements when the anchor is made with welding or screwed bolts. Anchored bearing should be designed considering the possibility to be removed and replaced.

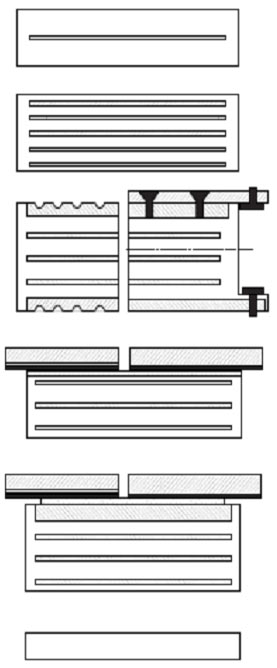

- Type A: Laminated bearing fully covered with elastomer com prising only one steel reinforcing plate

- Type B: Laminated bearing fully covered with elastomer comprising at least two steel reinforcing plates

- Type C: Laminated bearing with outer steel plated (profiled or allowing fixing). NOTE the sketch shows examples of a few fixing methods can be used by agreement

- Type D: Type B with PTFE sheet bonded to the elastomer

- Type E: Type C with one outer plate bonded to the elastomer and PTFE sheet recessed in the steel.

- Type F: Plain pad bearings and strip bearings.

The figures provided in this table relate to Type B and Type C bearings in accordance with EN 1337-3.

The different values shown below may be changed as a function of the actual stresses on the bearing

involved